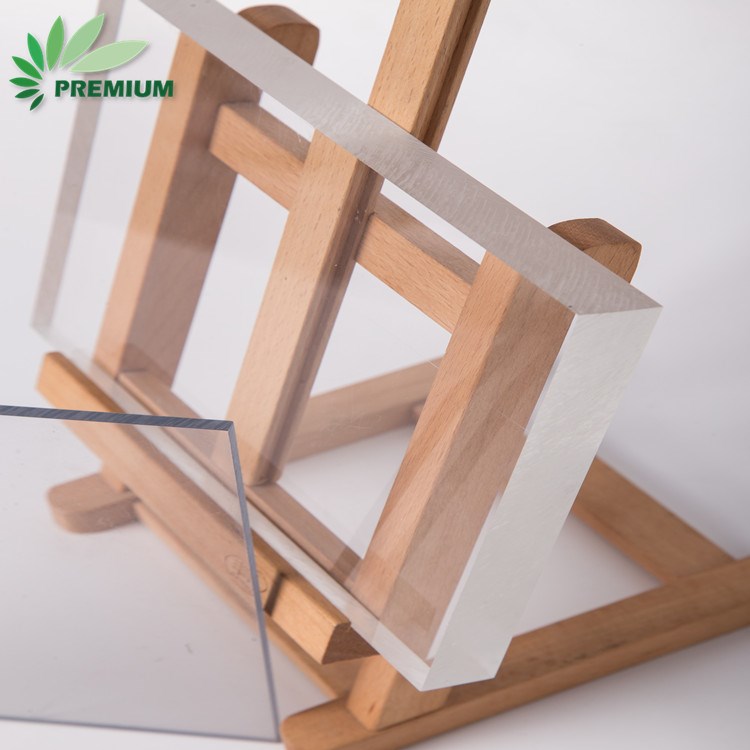

Extruded Acrylic Sheet

- PREMIUM

- Stadt Jinan, Provinz Shandong

- 5-7 Tage

- 1000tons pro Monat

Zusammensetzung: Neumaterial

Dicke: 1,2 mm bis 8 mm

Breite: 1250 mm bis 2050 mm

Länge: Als Ihre Anforderung

Extruded Acrylic Sheet

1. Production Technology:

Extruded acrylic sheet is extruded at high temperature

Cast acrylic sheet is made by the mould.

1st: clear and fix the mould

2nd: fill the liquid mma, colored or transparent as customer requirements. 13pcs-15pcs in one frame.

3rd: boiled 3-4 hours

4th: dry 3-4 hours

5th. get the acrylic sheet with pvc edge(1250x2450mm, 1250x1850mm, etc)

6th: laminated double sides brown paper or pe film, custom logo available

7th: cut off pvc edge as customer requirement(1220x2440mm, 1220x1830mm, etc), if customer need size 1250x2450mm with pvc edge, then packing directly

8th: wood pallet or iron pallet packing

2. Price: cast acrylic sheet price is higher than extruded acrylic sheet because the material and process used in cast acrylic are more demanding then extruded acrylic.

3. Thickness:

Extruded acrylic sheet 1.2mm-8mm

Cast acrylic sheet 1.8-50mm,

Cast acrylic sheet thickness tolerance is larger than extruded acrylic sheet.

4. Performance:

Cast acrylic sheet has high technological performance and is suitable for various processes.

It has no crystal point on the surface and relatively high transparency.

Extruded acrylic sheet the edges and corners will be yellow, the surface will easily produce crystalline points, the process performance is weak.

5. Transmittance:

Cast acrylic sheet has higher transmittance than extruded acrylic sheet.

6. CNC Machine Engraving Processing:

Cast acrylic sheet will be no holes during the process of CNC machine engraving.

7. Laser Cutting

Extruded acrylic sheet smells bad and smoke is bigger whilc laser machine cutting.

So please kindly choose right acrylic sheet as budget and different applicatin.

Following is cast acrylic sheet brief:

Sheet 1:

Premium Acrylic Sheet

| Cast Acrylic Sheet | Extruded Acrylic Sheet |

Clear/Transparent Acrylic Sheet | Colour Acrylic Sheet | |

Translucent Acrylic Sheet | Opaque Acrylic Sheet | |

Frosted Acrylic Sheet | Mirror Acrylic Sheet | |

Pattern Acrylic Sheet | Glitter Acrylic Sheet | |

Opal Acrylic Sheet | Crystal Acrylic Sheet | |

Day-Night acrylic sheet | PS sheet | |

Custom acrylic item production | ||

Sheet 2:

Color | Dimension(mm) | Thickness(mm) |

More than 200kinds of color | 1020*2030 | 2-3-5-8mm |

1220*1830 | 2-25mm | |

1220*2440 | 2-25mm | |

1500*3000 | 3-20mm | |

2000*3000 | 3-25mm | |

Custom acrylic size production | ||

Sheet 3:

Color | Dimension(mm) | Thickness(mm) | |

Clear(Transparent) | 1220*2440 | 1220*1830 | 25 |

1210*2430 | 1210*1820 | 30 | |

1200*2400 | 1200*1810 | 35 | |

1190*2390 | 1190*1800 | 40 | |

1160*2360 | 1160*1770 | 45 | |

1140*2340 | 1140*1750 | 50 | |

Custom acrylic color production | |||

Sheet 4: Plexiglass Physical Properties:

1. | Density | 1.2g/cm3 |

2. | Rockwell Hardness | M-100 |

3. | Tensile Strength | ≧70Mpa |

4. | Impact Strength (Charpy Unnotched) | ≧13kJm2 |

5. | Elastic Modulus | ≧3000Mpa |

6. | Elongation At Break | ≧3% |

7. | Light Transmittance | 93% |

8. | Refractive Index | 1.49 |

9. | Vicat Softening Temperature | 100℃ |

10. | Thermal Forming Temperature | 140-180℃ |

11. | Dielectric Strength | 20kv/mm |

12. | Absorption(24HRS) | 0.30% |

Sheet 5: Cast Acrylic Sheet Machining Property:

1 | Cutting Acrylic | CNC Machining | Laser Engraving |

2 | Surface Finishing | UV Printing | Drilling |

3 | Shaped | Thermo Bending | |

4 | Thermoforming | Blister | Blow Molding |

5 | Trimming | Flame Polishing | Edging |

6 | Gluing | Glue |